Barely Chair

Material Experiments

The Barely Chair is a visually and structurally compelling physical object created especially for French design brand Roche Bobois. Co-designed with architect Danielle Connelly, this luxury home good defies the laws of physics through its single-material, proprietary textile construction.

Its design required unique research into mold-making methods. Our studies tested different opportunities with the intent to develop a mold with unique de-molding capabilities to disguise the exit points of the molding rods, and to create interior voids which increased the strength of the chair. With an understanding that the final product would need to be attractive, we all the while were hyperconscious of how these methods would each potentially drive the final shape of our chair. The result yielded a sturdy, effective, and aesthetically impressive design.

Learn more about the Barely Chair’s molding and form experiments in the Lab.

FIBERGLASS

HAND CROCHETED (SINGLE CROCHET, SIZE 4 HOOK)

Composite materials are traditionally used as built up layers of perpendicular woven fiberglass to provide fiber strength in all directions. We hypothesized that a crochet or knit material, whose interlocking loops and omni-directional fibers traditionally create stretch, might provide more strength and stability when paired with resin.

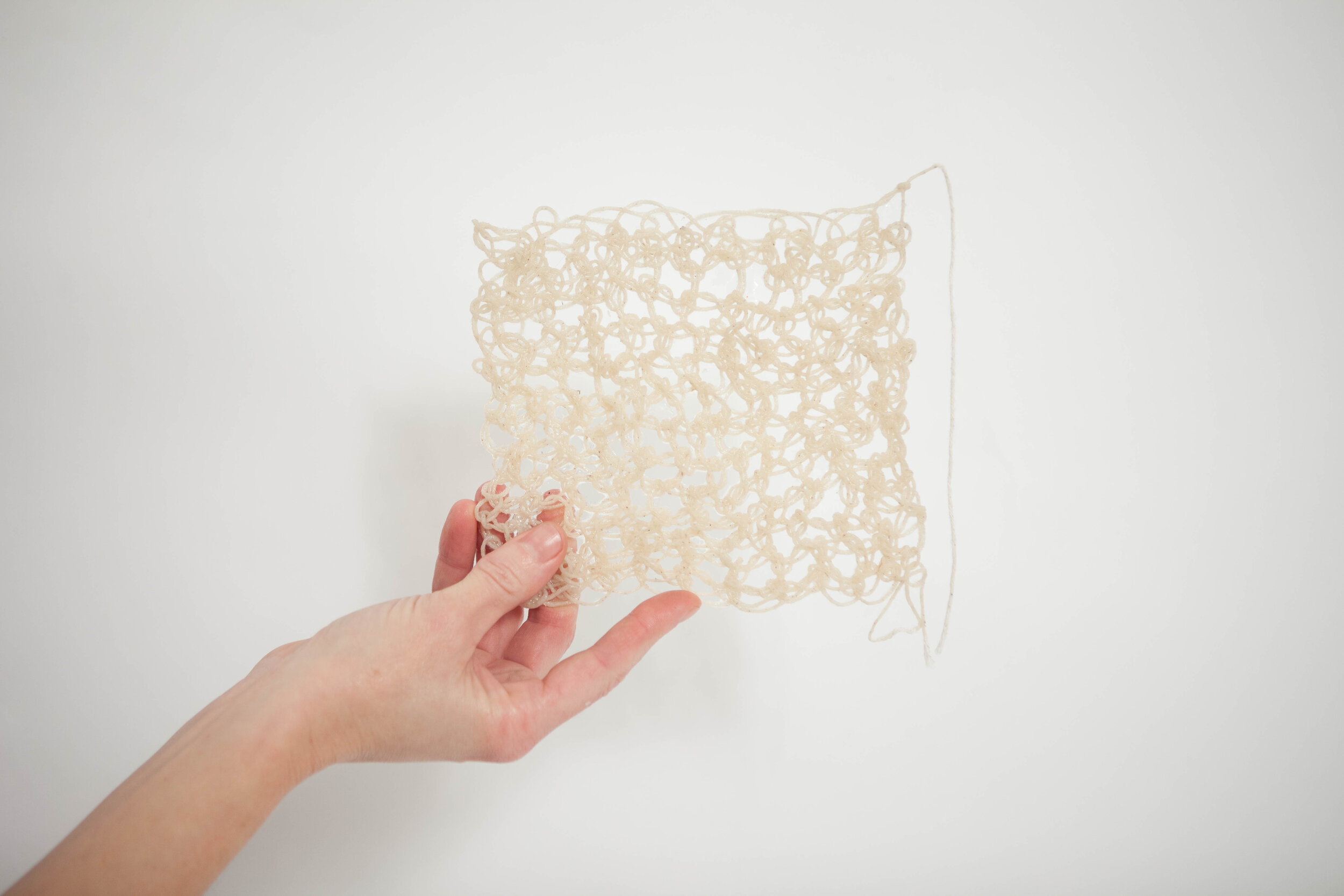

COTTON

HAND CROCHETED, LACE CROCHET STITCH

Because cotton has long staple fibers and is so absorbent, it created a promising composite.

KEVLARSIZE 138, TEX 120 HAND CROCHETED

SINGLE CROCHET. SIZE 10 HOOK

This particular Kevlar was not absorbent at all and thus was one of our weakest samples.

BASALT

WOVEN (PLAIN WEAVE)

Basalt fiber is a material made from lava rock with similar properties to carbon fiber but at a much more affordable price.

BASALT

MACHINE KNIT

Basalt is a bit too brittle to stand up to the rigors of a knitting machine. A multi-ply thread might be less likely to break and more absorbent.

BASALT

WOVEN (PLAIN WEAVE)

Woven basalt in a corner geometry. The qualities of woven material and thin fibers created a less stable corner than other materials we tested.

FIBERGLASS

HAND CROCHETED (SINGLE CROCHET, SIZE 4 HOOK)

Roving showed much more strength in compression when the material was triangulated into a corner shape.

COTTON ROD

12-PLY, KNOTTED

We went back to our 3rd grade roots with this "friendship bracelet" style experiment, which resulted in a flexible and strong (but not load-bearing) rod.

PAINTING VS SCRUNCHING

Painting, rolling and scrunching or kneading the epoxy onto the material each yielded varying results depending on the material. Cotton created the strongest composite with a kneading method, which allowed the fibers to become more fully impregnated, but that also loosened some fibers, creating sharp spurs once the resin cured.

COTTON COLUMN & CORNER

Hand crocheted 24-ply cotton string makes extra chunky, extra strong material. A hollow column constructed in a circular knitting style gave way to a corner to create our strongest geometry yet. It was particularly impressive in compression. One key insight of our vast material experiments was that circular knit patterns coupled with cylindrical geometry yielded extremely robust properties. This became a basis of all our future models

DRAPING

Based on a background rooted in sewing, our forms initially began as flat patterns that were draped over a form. Seams were sewn together directly on the form, but this created weak points in our composite.

EPOXY RESIN

ENTROPY RESINS SUPER SAP CLEAR EPOXY RESIN & HARDENER

To provide some consistency in testing, we used the same eco-friendly epoxy in all our composite materials.